Automatic vertical screws counting packing machine

Advantages

Vertical machines have many advantages in screw point packaging. First of all, the vertical machine can efficiently complete the automated packaging of screws and improve production efficiency. Secondly, the vertical machine has a precise counting function and can accurately count screws, avoiding errors and losses that may be caused by manual counting. In addition, the vertical machine also has the ability to quickly adjust and adapt to different specifications of screws, improving the flexibility and adaptability of production. Most importantly, the vertical machine is able to maintain the stability and quality of the packaging, ensuring that the screws are not scattered or damaged during transportation and storage. To sum up, the vertical machine has obvious advantages in improving production efficiency, accurate counting, and providing stable packaging. It is an ideal choice for screw point packaging.

Main performance and features

1. The photoelectric detection system is stable and reliable, ensuring the integrity of the bag's trademark

2. Intelligent temperature control meter control, firm seal, exquisite packaging

3. The vibrating plate and track are customized to ensure correctness

4. Automatic alarm when there is no material or material jam, easy to understand the working status

5. Exquisite touch screen display, supporting Chinese and English systems

Package samples

Parameters

|

Model |

BL-160S |

|

Film width |

Max.620mm |

|

Bag Width |

20-100mm |

|

Bag Length |

30-200mm |

|

Film roll Diameter |

Max.400mm |

|

Packing rate |

10-80bags/min |

|

Measurment range |

Can be customized |

|

Power |

220V,50HZ, Single Phase |

|

Machine size |

Customized models, subject to actual conditions |

|

Machine Weight |

450kg |

|

Suitable Material |

BOPP,PE,OPP/CPP,OPP/PE |

The main part of the machine

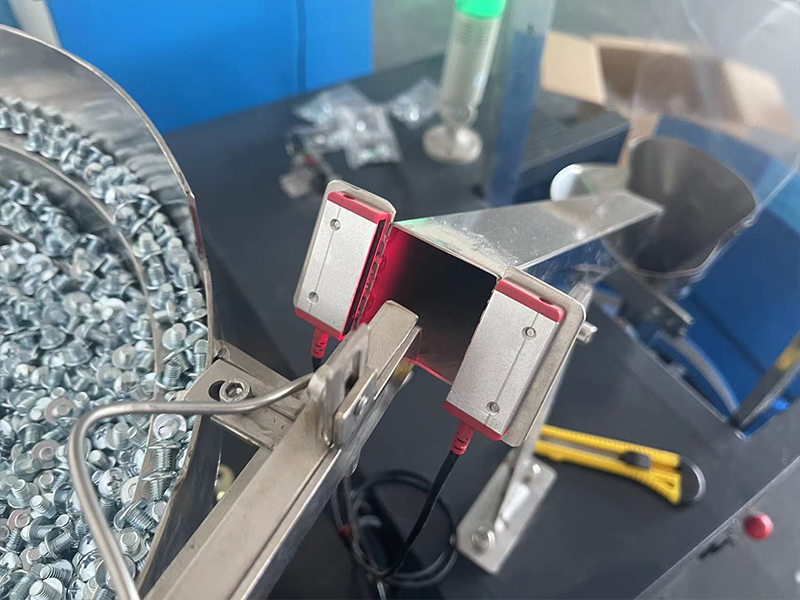

Automatic counting

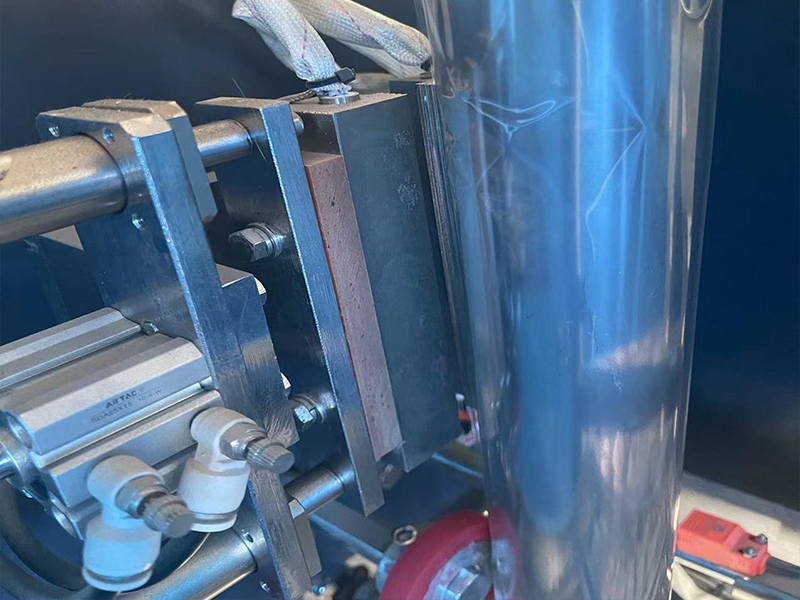

Back sealing

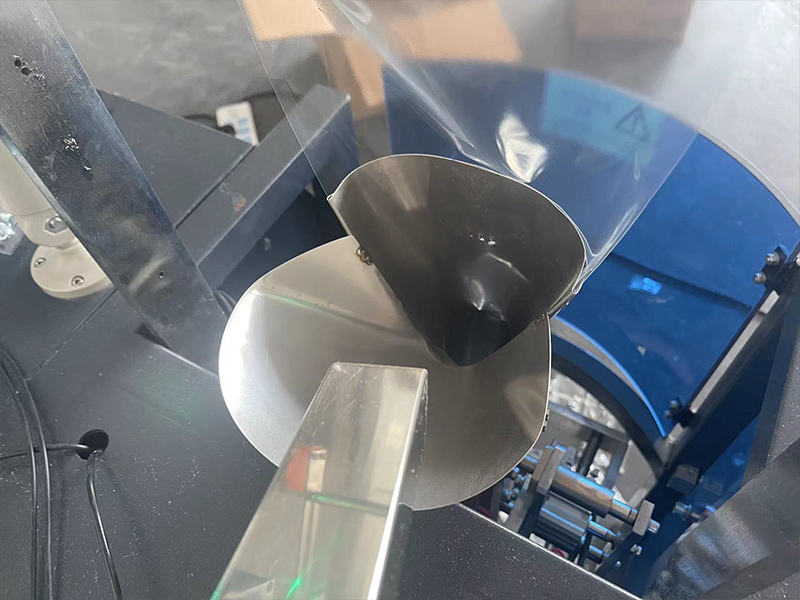

Bag former

End sealing

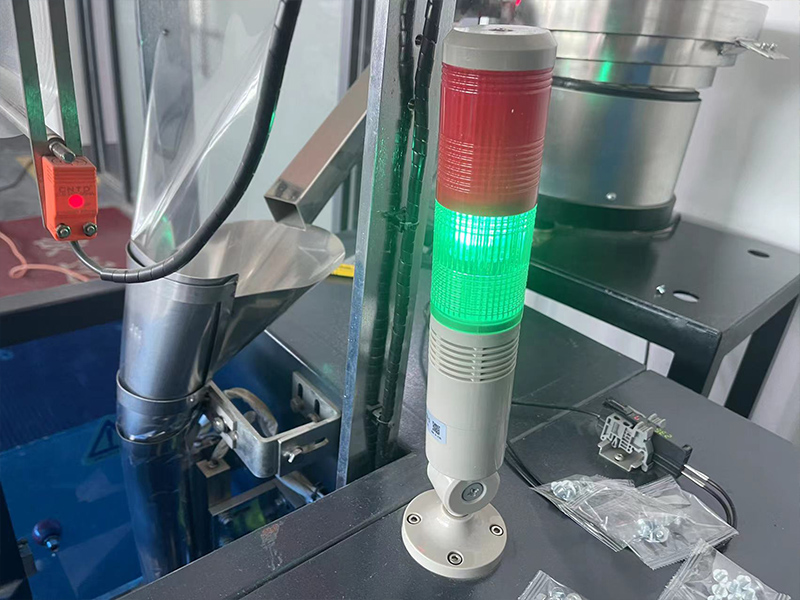

Fault alarm

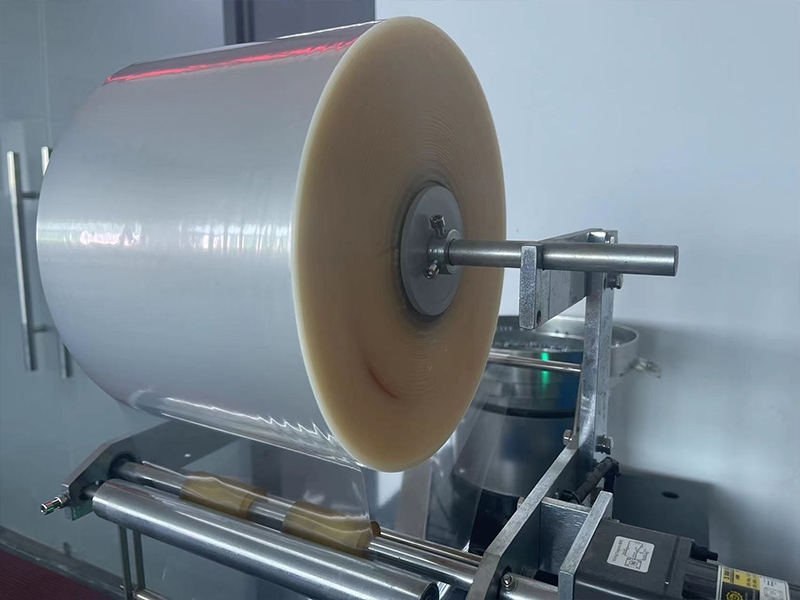

Film roll holder