Full Automatic Face Mask N95 Pillow Packing Machine

Product Introduction

1. Three servo control, bag length is set to cut, no need to adjust the empty walk, material automatically film, material waiting, one step in place, save time and film.

2. Color touch screen control, convenient and fast setting of parameters, and can store 100 kinds of packaging parameters.

3. Failure self-diagnosis function, the fault display is clear at a glance.

4. High-sense photoelectric eye color scale tracking, digital input sealing position, to make the sealing position more accurate.

5. Temperature independent PID control, better suitable for various packaging materials.

6. Positioning and shutdown function, non-stick knife, no waste of envelope.

7. Simple transmission system, more reliable work, and more convenient maintenance.

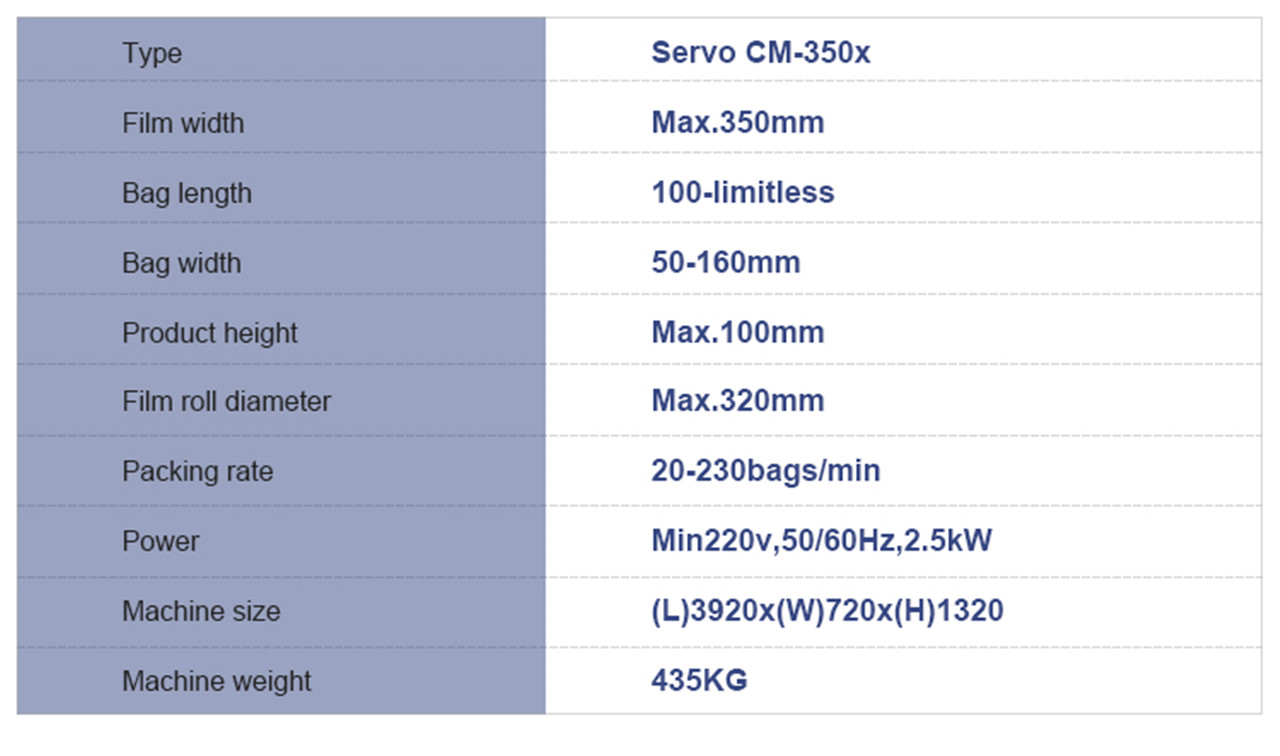

Parameters

|

Type |

CM-350X servo |

|

Film width |

Max.350mm |

|

Bag length |

100-limitless mm |

|

Bag width |

30-160mm |

|

Product height |

Max.60mm |

|

Packing speed |

40-230bags/min |

|

Film roll diameter |

Max.320mm |

|

Power |

220V,/50/60HZ,2.6KVA |

|

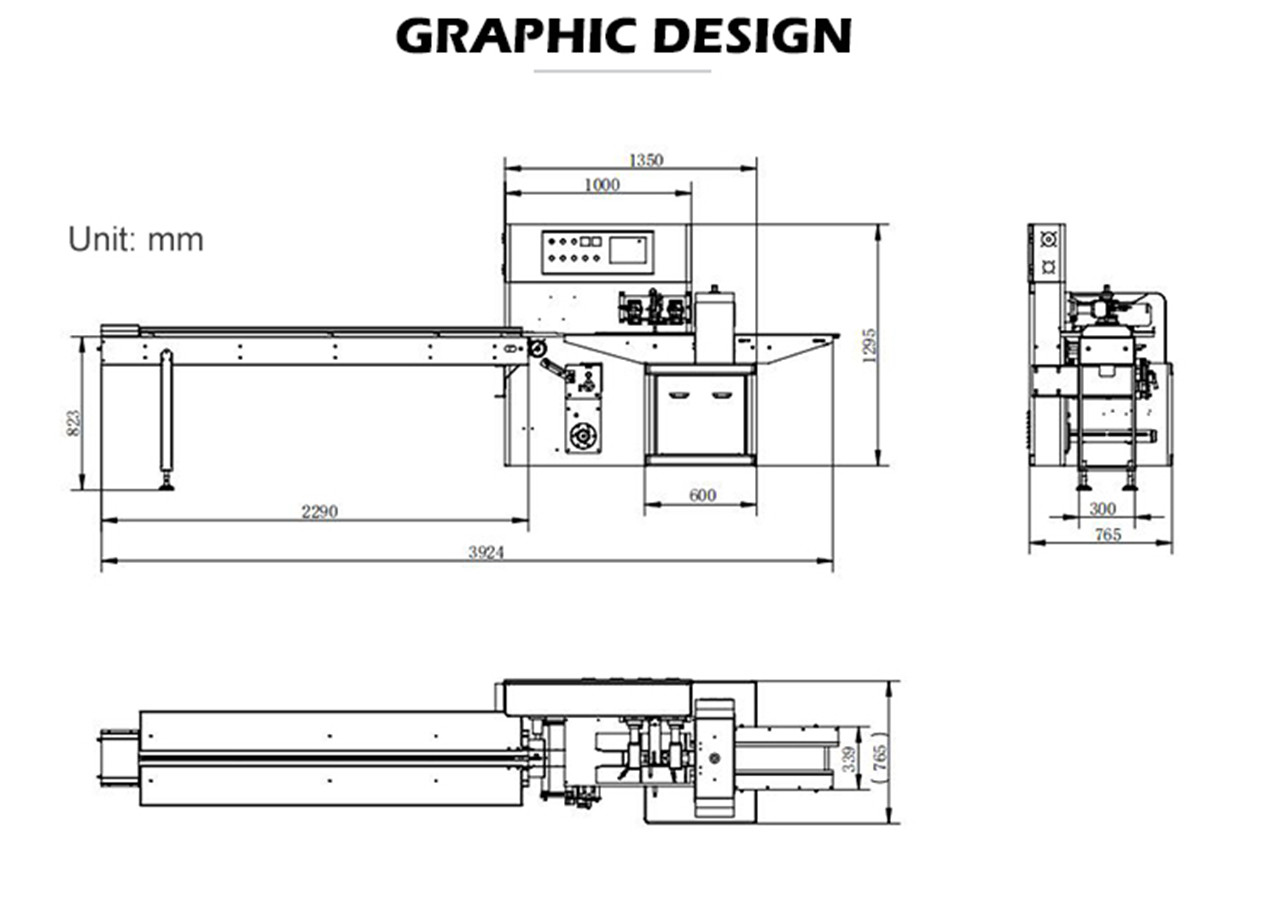

Machine size |

(L)3770x(W)670x(H)1370mm |

|

Machine Weight |

450KG |

|

Suitable film |

PE.BOPP/CPP,BOPP/PE etc. |

|

Remarks |

Inflatable devices can be added) |

The main part of the machine

Multilingual screen

Control panel

Optical fiber sensors

Bag former

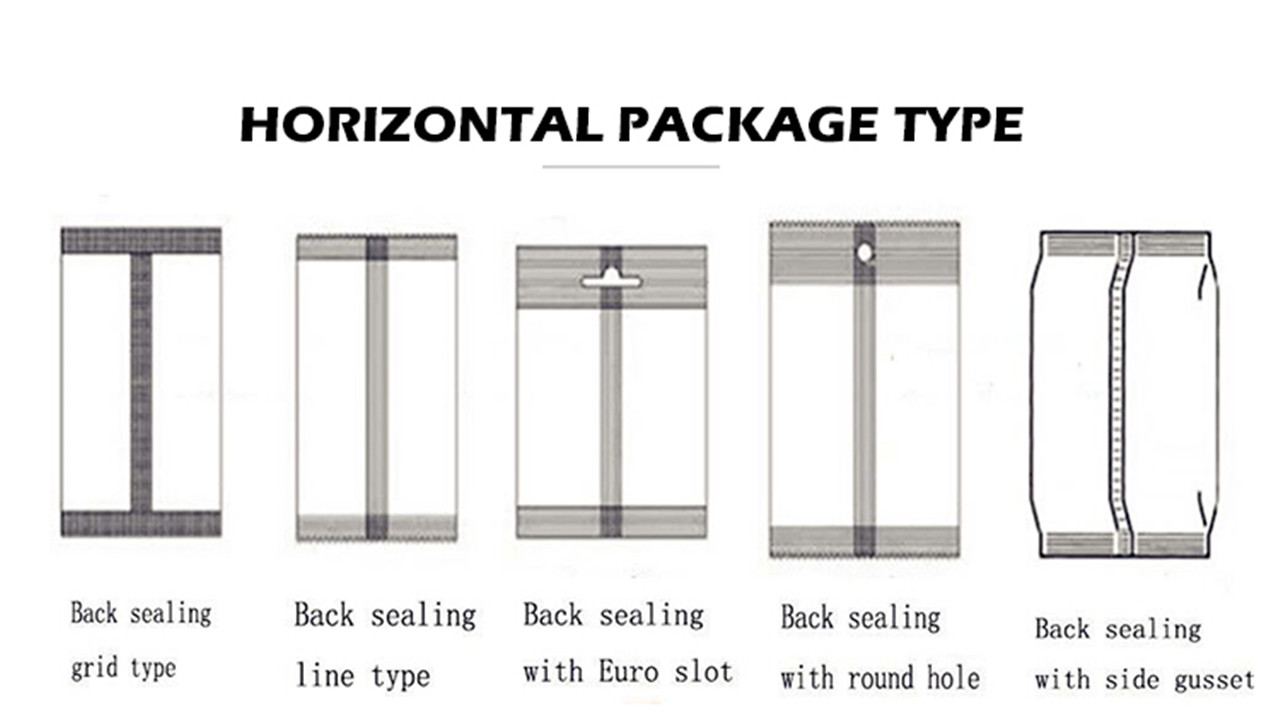

Back sealing

End sealing

Film roll holder

Adjustable holder

Tailstock

Advantage

Full automatic: It can connect with the production line to realize unmanned operation.

High efficiency: Packing speed 40~230bags/min, 2400-13,800bags/Hour, -No empty bags:Optical fiber sensor will help to confirm if there is product in and control to wait.

Stable performance: Machine’s service life can exceed 10 years if operate correctly.

Better after-sales service: Customer can get help whenever you need.